Since I was last here I have completed a base place for the rectifiers and just this evening, I managed to actually get the two main heat sink plates on. This turned out to be a tough decision as I hadn't really thought about the process of attaching the output devices to the slab of H/S. As it turned out I tapped two holes 104mm apart for the M3 screws. If I can't get the board to match up, I'll just wire them to the boards.

I have also been rather busy trying to get my speakers to some sort of stage were I could get them out of the garage and into the lounge, so it's been a busy couple of weeks.

Yes they are monsters, I had no idea that they would look this big. But the wife has said very little about them, so big relief.

The Image speakers sitting next to them are just over 1m high so it shows how large they are.

The rear was made into a box (covered in cork) to place the X/O's in and also create two side

bits to place two bags of 'shot' in. So as to give a little stability to the base. The lid fits snug on top. The front panels are cheap (well cheapish) pine which I coated in oil (4 coats). I used two cable glands (one at the front and one at the rear) to hold the speaker leads in place. Bugger paying ridiculous amounts of money for fancy connections that hardly ever get used. These turned out to be about $3 dollars each as opposed to $140 for fancy ones........

Don't even have an amp to drive the bass drivers yet. That'll be a long way off.

Right ........back to the amp.

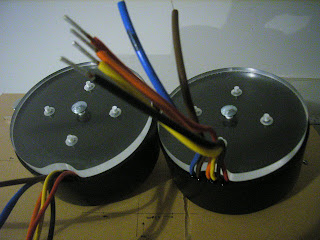

Right..............you can see the two side plates have been attached and I also put the two thermistors (see power supply schematic on Nelsons page) down the back by the ground. And also put in a power switch, which was originally going to go in the front. But I have decided to keep this nice and clean, not even an LED is going to find it's way onto that nice piece of wood.

Fourteen screws and washes later.............. I placed some silicon and the back as well to try and make good contact between the two surfaces.